Decarbonization by Producing Medium Temperature Hot Water with Vacuum Tube Solar Collectors

Process Heating and Industrial Decarbonization with Vacuum Tube Solar Collectors

For Industries using Combustible fuel in the production of Medium Temperature Hot Water for their hydronic heating and cooling processes, Vacuum Tube Solar Collectors are the path to decarbonization and migration to a more sustainable operation.

Introduction

Multiple Industries across Canada and the US use Natural Gas, Propane, Fuel Oil or other types of combustibles to produce medium temperature hot water (MTWH) ranging between 140°F (60°C) and 212°F (100°C) for their industrial Hydronic Heating and Cooling Processes. The reasons why combustibles are still used for MTWH is that more sustainable technologies such as Conventional Air to Water Heat Pumps, Geothermal Heat Pumps, or heat recovery devices in large buildings can not produce hot water above 131-140°F (55-60°C) or project cost for cascading heat pumps to produce MTHW, combined with low combustible energies' rates in many states and provinces, has a long payback period. This leads to decision makers hesitating from investing in this kind of projects.

Extreme Canadian Winter (Same as in some parts of the US such as Alaska, Vermont, Massachusetts, Maine, New Hampshire, etc...), with less sunny hours between November and March, requires a reliable yet sustainable energy source especially for industries with continuous operation and constant hydronic process heating and cooling demand. These constraints make technologies (such as Flat Plate Solar Water Heating Panels - Glazed or non Glazed) that do not perform in Freezing Winters not suitable for this type of processes.

Our Evacuated Tube Solar Collectors have been designed to perform in extremely cold weathers such as in Canada and the northern part of the US. Vacuum Tube Solar Collectors thermal efficiency declines from 42-43% in the summer to 37-38% in winter. When Vacuum Tubes are installed in series MTHW is produced as soon as solar panels get sun exposure (regardless of ambient temperature or wind speed). Flat Plate Solar Collectors have Zero % Thermal efficiency in Canadian Winter.

Further Readings:

To know more about Vacuum Tube Solar Collectors, how do they work? or why the do perform in extreme Canadian Weather, please read the below blogs:

Things to consider for Medium Temperature Hot Water Production with Sustainable Energy Source

Process Operating Conditions, such as Temperature, Pressure, Fluid Type, etc... impose multiple constraints that influences the design and configuration of any solar thermal system. In industries with already established Processes, Solar thermal system design needs to be aligned with existing hydronic heating process and not the opposite. Selection of each components of a Vacuum Tube Solar Heating System (as in the below Schematics) is dependent on these constraints.

- Heat Transfer Fluid Boiling Temperature: In order to have heat exchange between Solar Heat Transfer fluid (HTF) and Process Heating Fluid (PHF) via the Heat Exchanger, Solar HTF supply and return temperatures need to be higher than the process heating supply and return temperatures. Also HTF Boiling temperature should be way higher than the maximum operating temperature in solar HTF closed loop at all time. HTF is most of the time a water glycol mix, and when operating temperature exceeds boiling temperature, water and glycol separate and water becomes steam and leaves the solar closed loop through the automatic air vent, usually installed at the highest point of the solar installation.

- Temperature and Pressure Ratings of Solar Closed Loop Components: For the integrity of the installation, all components (such as pipes, Fittings, Pump, Gaskets, Sensors, Thermal Wells, etc....) shall be rated to properly function at the operating pressure and temperature of the HTF (with a certain safety factor).

- Process Heating Demand Vs Solar Thermal Supply: The hardest task in solar projects is to match supply and demand. By doing so in the summer season (where most of the sunny hours are), we end up with a heat shortage (Supply less than demand) in winter since we have less sunny hours in winter. When Sizing the Solar Thermal System winter supply for winter demand, we end up with excess heat in the summer season that we are forced to dump. Designer needs to address this dilemma with customer, either accept heat dump in the summer, or have a kind of backup heat source in winter.

- Potential for Seasonal Thermal Energy Storage: Seasonal Thermal Energy Storage allows solar system to be designed to annually produce the annual demand. Thermal Storage will store the excess heat in the summer and allows it to be used in the winter when thermal energy production is less than thermal energy demand.

Our Best in Class Vacuum Tube Solar Collectors

The Nature of Evacuated Tubes - Thermal Stacking Vs Thermal Efficiency

Vacuum Tube Solar Collectors are complex heat exchangers having one function to do: transfer heat from the sun to a fluid circulating inside the Evacuated Tube Solar Collector's Manifold Header.

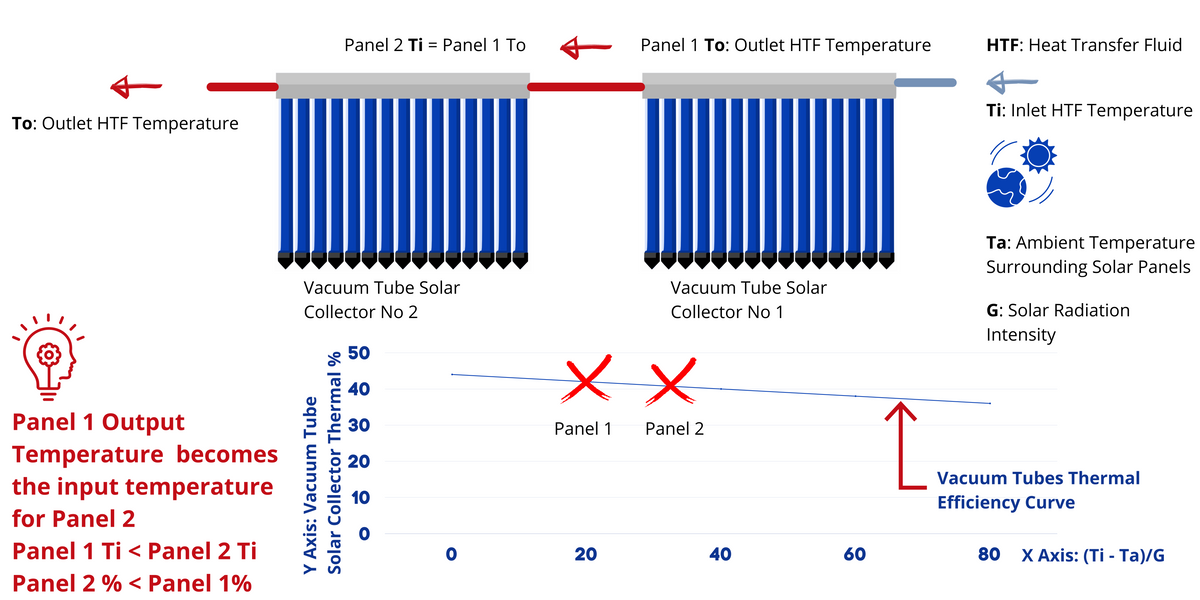

By fulfilling the heat transfer function, Vacuum Tube's output Temperature is always higher than inlet's temperature (asecond law of thermodynamics). When Evacuated Tube Solar Collectors are stacked in series, the outlet temperature of the first panel becomes the inlet temperature of the second one which increases the output temperature of the second panel to even higher temperature. By Thermally Stacking a third, fourth, ..... Nth Panel in series we gradually increase the Nth Panel Outlet Temperature to the desired process heating required supply temperature.

As we can see from the above Thermal Efficiency Curve, Panel's thermal efficiency decreases when the difference between Panel's Inlet Temperature and Ambient Temperature divided by Solar Radiation Intensity increases. For a short period of time, we can assume that Solar Radiation Intensity and Ambient Temperature are constants. In that case, Panel's thermal efficiency depends on inlet temperature and decreases when inlet temperature increases. That means the second panel in series with the first one is less efficiency that its predecessor in the same row.

In light of the above, the Number of Panel in Series, should be properly calculated to supply heat transfer fluid at the desired operating process heating supply temperature (plus temperature losses at the heat exchanger). Designer should always avoid overheating HTF above desired operating temperature since it increases the Number of Panels and lowers the overall thermal efficiency of the whole solar system.

Example of MTHW Production with Evacuated Tubes Solar Collectors: Heating Sea Water from 4°C (39.2°F) to 85°C (185°F)

A good example of Medium Temperature Hot Water Production is Sea Salt Production from Sea Water. In this type of application, Salt needs to be extracted from water pumped from the sea. For that to happens, Sea Water is sucked by a pump, from the bottom of the sea, at 4°C (39.2°F) and heated to 80°C (176°F). At 80°C (176°F), salt crystalizes and can be separated from water.

To do so we have simulated our Evacuated Tube Solar Collectors, in Quebec City (QC) area for 8760 hours per year using Quebec weather data. HTF circulating in the Solar Panels is Solar Propylene Glycol (50% concentration - Operating Temperature Range -46°C (-15°F) to 163°C (325°F) and a stagnation temperature of 219°C (425°F) in a closed loop Circuit). HTF gets heated by Evacuated Tubes and Heat Sea Water via a Shell and Tube or Flat Plate Titanium Heat Exchanger. A sample of the obtained result is shown below:

The above photo presents simulation results for the First day of January and shows thermal cascading process: Temperature increases and thermal efficiency decreases from one panel to the next one in series (when moving along Heat Transfer Fluid flow). For an Entering temperature of 4°C (39.2°F), HTF leaves the row of six panels at 80.3 °C (176.54 °F) when Solar Radiation Intensity of 49 degree titled panel is around 800 Watts/m². Leaving HTF temperature changes with changing solar radiation intensity on hourly basis. To maintain a constant temperature output, HTF flow can be either increased or decreased by a temperature controller (simulation was done with 0.5 US GPM HTF flow through the 6 panels series).

The above photo presents simulation result for the end of June. Here too, Temperature increases and thermal efficiency decreases from one panel to the next one in series (when moving along the flow of Heat Transfer Fluid). For an Entering temperature of 4°C (39.2°F), HTF leaves the row of six panels at 92.43 °C (198.37 °F) when Solar Radiation Intensity of 49 degree titled panel is around 1000 Watts/m². Leaving HTF temperature changes with changing solar radiation intensity on hourly basis. To maintain a constant temperature output, HTF flow can be either increased or decreased by a temperature controller (simulation was done with 0.55 US GPM HTF flow through the 6 panels series).

Conclusion

Medium Temperature Hot Water (MTHW) production with Evacuated Tube Solar Collectors has a promising future in Canada and the United States in reducing carbon's footprint of the industrial sector. Financing renewable energy projects is much easier than it used to be few years ago, multiple green bond firms and utility companies' incentives make this type of project more appealing from a financial perspective: Shorter Pay Back Period, Zero Down Payment, Mortgage Amortization Period equal to a Portion of Solar Panels Lifespan, Mortgage Payment is compensated by Energy Savings, etc....

The key success factor in this type of projects is to properly match supply of energy produced by Solar thermal with Process Heating demand. Daily or Weekly thermal storage of thermal energy can help streamline the supply of thermal energy and reduce dependence on backup heat.

excellent expiation

Can evacuated tubes be adjusted or designed to output different temperatures? I would want the hottest output possible.