How to turn wasted heat into cash in Buildings with simultaneous heating and cooling demand?

How to Generate Savings with Heat Recovery in buildings with simultaneous heating and cooling demand?

Many buildings have cooling and heating demand at the same time. A lot of money is wasted when paying utility companies to buy energy for generating heating and cooling at the same time. This blog explains how to recover heat and reduce annual utility bills.

Introduction

Residential Buildings', across Canada and the US, Space heating/cooling and Domestic Hot Water (DHW) heating demand represent 75% of the their annual utility bills. Many Days of the years, we buy electricity for Cooling (which is no more than heat extraction from an indoor space) and at the same time we pay utility bill for electricity or natural gas to either produce domestic hot water heating or heat a pool or SPA.

In other terms, we pay money to throw heat from our indoor spaces in the summer to the outdoor and we pay money to heat our DHW and and pool. The ideal scenario will be to recover the heat evacuated from the indoor space and use it to partially or fully to produce DHW or Heat a pool or a SPA. With today's available technologies, that is possible, but who does that? The answer is very few.

The heat recovery potential in commercial and / or residential buildings with simultaneous heating and cooling demand is much higher, since the amount of heat that can be recovered and used in other processes is larger and can justify the capital investment involved in hiring professionals to design such as system and to buy the necessary equipment.

A large factory with immense indoor manufacturing space with continuous Space Cooling demand and process heating demand is a golden opportunity for heat recovery and energy savings. Heat extracted by the cooling system can be converted to hot water, by using water source heat pump or chiller, and recovered hot water can be used (with or without thermal storage) to provide hot water for the heating process.

Capital Cost, operating constraints, availability of skilled trades, etc.. are factors that discourages buildings' owners and operators from getting into such journey. This blog will explain how to mitigate those factors and to reduce their impacts on finances and operations.

Step 1: Know your Seasonal / Annual Energy Portfolio

Heating and Cooling demands are usually cyclical. Trends repeat themselves periodically. Space Heating and Cooling demands for buildings' envelopes have annual trends , DHW heating can have daily, weekly, seasonal or annual trends.

Process Heating or Cooling trends depend on operation and can not be simulated with energy simulation software.

Having a clear and precise behavior of the energy demand is crucial to avoid oversizing the heat recovery system. Oversizing means increasing cost, lengthening payback period and may financially kill the project.

Most Canadian homes spend 54% of their utility bill on Space Heating and Cooling and 20% on DHW Heating. Simultaneous Cooling and Heating is possible in the summer (June, July and August) with both space cooling demand and DHW heating demand.

In order to minimize project cost, Heat Recovery System shall be sized in order to recover the heat extracted by cooling process into DHW heating. The amount of recovered heat from cooling should never exceed DHW heating demand. The purpose is to be able to utilize all the recovered heat and to minimize dumped recovered heat.

Step 2: Know your Process using the Recovered Energy

Recovering heat from one process (such as Cooling) and using it in another one (such as Process or DHW heating) requires that the quantity and quality of recovered heat be suitable for the process using that heat. Heat recovered from a cooling process with water source heat pump requires that heat pump condenser's output is higher that Domestic Cold Water (DCW) incoming temperature. If this condition is not met, recovered heat is useless for DHW heating. Heat Recovery / Heat Transfer Process is successful when the following conditions are met:

- Heat Shall be Recovered at a temperature higher than the one required by the process using that heat. Heat Travels between two mediums from the higher temperature one to the lower temperature medium.

- Heat Transfer fluid shall allow simultaneous cooling and heating between the two processes.

- Heat Exchangers between the two processes shall be properly sized for the worst operating conditions.

- Heat Exchangers between the 2 process shall be constructed of materials suitable for the heat transfer fluids of both processes. Example: When trying to heat a pool from wasted heat by the home cooling process, a titanium heat exchanger shall be used since titanium is resistant to chlorinated water of the pool.

Step 3: Incorporate Heat Recovery and Heat Recycling into your Heating/Cooling Design

Once Energy Demand profile is Know and Heat recovery and recycling process are identified (as explained above), designer should now incorporate the heat exchange process (heat recovery / heat usage) into his design. This blog will show you how to do that by using a real life example: a commercial laundry located in a basement of commercial building in downtown Montreal (QC). The place has no exposure to the outside (no Windows, Doors, or Roof), and operating hours are 24 hours per day, 7 days a week. Dryers are Natural Gas Powered and do generate an immense amount of heat, at the same time washers do consumer DHW simultaneously during operating hours.

Dryers exhaust is a big 18 inches pipes that evacuate dryers hot air to the outside, however a sizable portion of dryer heat is radiated to the indoor space of the laundry, generating a continuous space cooling demand. The Laundry has no dedicated space cooling system, all what they have was a fresh air and exhaust system that keeps Carbon Dioxide concentration below 800PPM. Temperature inside the laundry is around 28°C in winter and above 35°C in the summer.

DCW enters in winter at around 4°C and in summer at around 16°C. Washers require domestic hot water at 49°C (120°F). Regardless of the season, there is always a DHW Heating Demand and a Space Cooling Demand, which is an opportunity for heat recovery with a smart simultaneous heating and cooling system. Customer wants to bring the space temperature down from 26-35°C down to 21-23°C in order to improve the health and safety conditions of his workers.

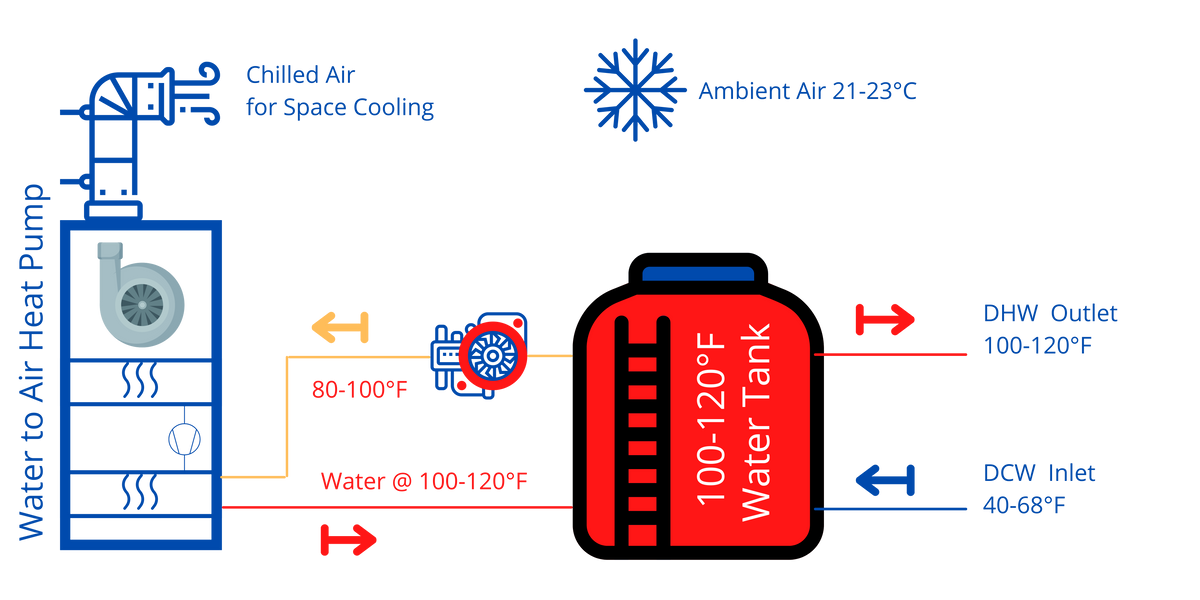

Space Heating is provided with Liquid Source (Water to Air) geothermal heat pump. It's a heat pump that has a water cooled condenser with a condenser water output temperature adjustable between 100-120°F. Unlike with a ground loop geothermal heat exchanger, Hot Water Generated by the heat pump condenser is accumulated in a thermal storage tank.

Temperature in the tank is increased by the heat dumped by the heat pump and domestic cold water enters the bottom of the tank and get pre-heated to 100-120°F, thus converting the extracted heat from the laundry (plus compressor mechanical work) to thermal hydronic heat that is used for heating or Pre-heating Domestic Cold Water. Existing Gas Power Boiler was left in place as an emergency heater for DCW or as a supplemental heater when pre-heated DHW leaves the Heat Recovery Tank at a temperature lower than 120°F.

With the above design we managed to improve the thermal comfort for workers and at the same time to reduce DHW heating energy demand by 2/3 annually, which brings the payback of this project to 7 years for a Heat Pump lifespan of 25 years (28% of Heat Pump Lifespan).

Conclusion

The bigger the project it gets, the more complex the heat recovery / heat recycling process it becomes. The above example is one of the easiest ones since it only involves air and water, two fluids easy to work with and safe for the environment. More Complex Projects with other fluids such as Glycol/Water Mixture, Refrigerant, etc.... require a deeper engineering design and for that we recommend you contact our engineering team for further help.

Building owners can install thermal storage systems such as freezers, chilled water tanks, or ice storage tanks to capture excess heat and later use it for heating. Read more: https://www.sequoia-global.com/waste-water-management-technologies/