Hydronic Chilled/Hot Water 1 Way Cassette Fan Coil, 4-Pipe System 208/230V-1Ph-50/60Hz, Capacity 1.5 Ton

$ 5,118.99 CAD

Payments: ![]()

![]()

![]()

Return Policy: We accept return within 30 days of receipt of your orders. Restocking fee applies on some returned Products. Returned Items shall have intact labels, packages and shall not have been used. for more info.

Full refund if you do not receive your ordered items.

Full refund if you do not receive your ordered items.  Partial Refund for partially not received or damaged items

Partial Refund for partially not received or damaged items

- Specifications

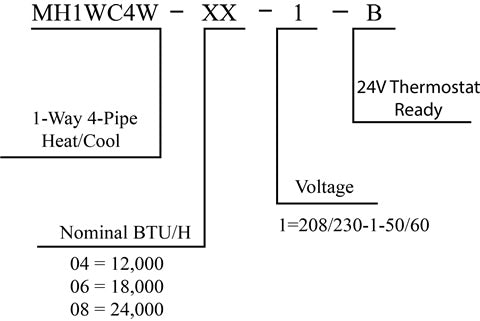

- Nomenclature

- Technical Documents

-

A. General:

- Unit is factory assembled and tested water fan coil.

- Unit is assembled with high quality.

- Contained within the unit s hall be all factory wiring, piping, and associated controls .

- Unit is shipped with integral PCB adapter Board for 24V field installed Thermostat.

B. Unit Cabinet and Cover:

- Cabinet is constructed of galvanized sheet metal.

- Cover compos ed of high impact polymers .

- Internally and externally insulated to ensure quiet operation.

- Cabinets are internally insulated from the factory. However, if these units are installed in high ambient/high humidity environments , additional filed installed external cabinet insulation may be required .

C. Fan Motor and Blower Wheel:

- Available in 208/230-1-50/ 60 VAC.

- Fan motor has three speed, direct drive, and PSC type.

- Fan motor is totally enclosed.

- Fan motor has internal overload protected.

- Radial blower wheel is dynamically balanced.

D. Air Distribution:

- Unit contains one automatic dis charge air louver.

E. Water Coils :

- Manufactured with water coils containing copper tubing mechanically bonded to aluminum fins.

- Coils are factory tested to 300 psig.

- Maximum design operating pressure s hall not exceed 200 psig.

- Coils are designed to accept an entering water temperature not to exceed 180°F.

- Both coils are equipped with manual air bleed ports which drain into the units internal drain pan.

- Secondary coil is in the re-heat position.

F. Drain Pan:

- Constructed of galvanized steel with baked on polyester powder coating and closed cell insulation.

- Unit contains internal lift pump and drain pan float s witch designed for evacuating condensate to the fan coil unit drain port level only.

G. Filters :

- Unit s hall contain two woven panel washable filter.

H. Fresh Air:

- Unit s hall be able to receive up to 10% filtered fresh air.

- Fresh air introduced shall be externally fan forced and externally controlled.

I Power & Safety:

- Fan coils are factory wired and tested.

- Fan coil includes a terminal block that is capable of incorporating a 24 VAC, field supplied thermostat.

- Fan coil contains a replaceable fuse on the low voltage side of the trans former.

- Coils shall be designed to accept an entering water temperature not to exceed 180°F

- Electrical line voltage connections s hall be made at the factory supplied terminal block.

- Factory wiring s hall be rated according to UL listing at the time of manufacturing.

-

Full refund if you do not receive your ordered items.

Full refund if you do not receive your ordered items.