How to save money with Hydronic Radiant Cooling?

HOW TO SAVE MONEY AND ENJOY THERMAL COMFORT WITH HYDRONIC RADIANT COOLING?

Do you already have an infloor heating loops? do you wanna increase your comfort level by adding cooling? are you getting an unbearable bill for forced air cooling?

Find out how you could use your existing infloor loops for cooling and save like 2/3 of your forced air cooling installation bill!

Introduction

HVAC systems in the majority of Canadian homes built pre-global warming era, are either hydronic or forced air Heating systems. Cooling in summer was not very common in the 1970s and even 1980s. Canadian households installation of Air Conditioning systems became popular in the early 90s when summer peak outdoor temperatures started going above 90 degree Fahrenheit.

Infloor hydronic radiant Heating loops account for a good portion of hydronic heating systems due to their unbeatable comfort level and their low cost when embedding infloor PEX loops in concrete slab.

Advantages and Disadvantages of Forced Air Cooling and Heating Systems

Most Forced Air systems in Canada are designed to perform fairly well in Heating Mode rather than Cooling Mode.

The majority of Canadian Homes have 8 months of heating demand and around 2 to 4 months of cooling demand.

To save space in Cottages and Bungalows, Air is supplied through floor grilles in ground floors, ceiling grilles in basements and floor grilles in upper floors.

Since hot air density is lower than cold air density, we used to end up with temperatures like 3 to 6 degrees Fahrenheit above set points in Upper Floors and like 3 to 6 degrees Fahrenheit below set point in Basements.

In a typical Canadian Cottage Served by a forced air system (with commonly one thermostat located in the ground floor usually set at 23 degree Celsius) we have like 26 degree Celsius in the upper floor (in extreme summer conditions) and like 18-20 degree Celsius in basement. Same temperature gradient occur in winter, since the heat injected by the forced air system escapes through windows and basement slab, leaving the basement at coldest temperature and upper floor at highest temperature.

Advantages and Disadvantages of Radiant Floor Heating Systems

Radiant Floor Heating eliminates the temperature gradient encountered in homes with forced air heating systems. Also we can not compare comfort level to the forced air system one since walking bare foot on a heated floor is priceless.

Also Radiant Floor Heating system using low temperature hot water as a fluid heat transfer is way more energy efficient than forced air system for two reasons:

First Low temperature hot water can be produced with Geothermal or Air to Water Heat Pump, bringing down the cost of heating energy production cost. Second Water is a better conductor of thermal heat and costs less than air to circulate all over the heated space.

Why Hydronic Radiant Cooling when you already have your Infloor Heating Loops or planning to have them in a new construction?

In the context of a new construction or an existing construction with infloor radiant heating loops, it makes a lot of sense to use the same loops for radiant cooling since it reduces significantly the ventilation load, Air duct sizes and project overall cost:

Radiant Cooling Chart for 6 inches spaces Uponor PEX Pipes with various above pipes thermal resistances

Radiant Floor Heating Chart for PEX pipes with various above pipes thermal resistances

Modern Homes built in compliance with minimum code energy requirements (2005 and after) require a nominal Heating Load between 10 to 14 Btu/hr/ft2 and a nominal Cooling Load between 8 to 12 Btu/hr/ft2. Looking at the above charts, we conclude that heating load can be entirely done with radiant infloor loops and cooling load can be partially done with radiant infloor cooling loops.

We should always remember that Fresh Air Ventilation Load and Humidification load can not be supplied by the infloor heating or cooling loops. Also the available Chilled Water Temperatures (Supply and Return Temperatures) as well as the finished floor (which dictates the thermal resistance above the infloor embedded PEX pipes) limit the amount of cooling the infloor radiant loops can provide.

for a medium chilled water temperature of 55 degree Fahrenheit (recommended in most residential applications), radiant cooling loops can supply a nominal cooling load of 12 Btu/hr/ft2 for a bare floor (R=0 thermal resistance above PEX pipes) and like 7-8 Btu/hr/ft2 for a floor with a thermal resistance around 1 (the case of most hardwood flooring, laminate and thick stone or ceramic tiles).

Radiant Cooling can supply between 50 to 85% of Nominal Cooling Load in residential application, thus saving you 50 to 85% of Air Ducting Cost and increasing your summer thermal comfort by eliminating the temperature gradient we usually have in conventional forced air systems. The lower the thermal resistance of flooring finish the higher is the saving.

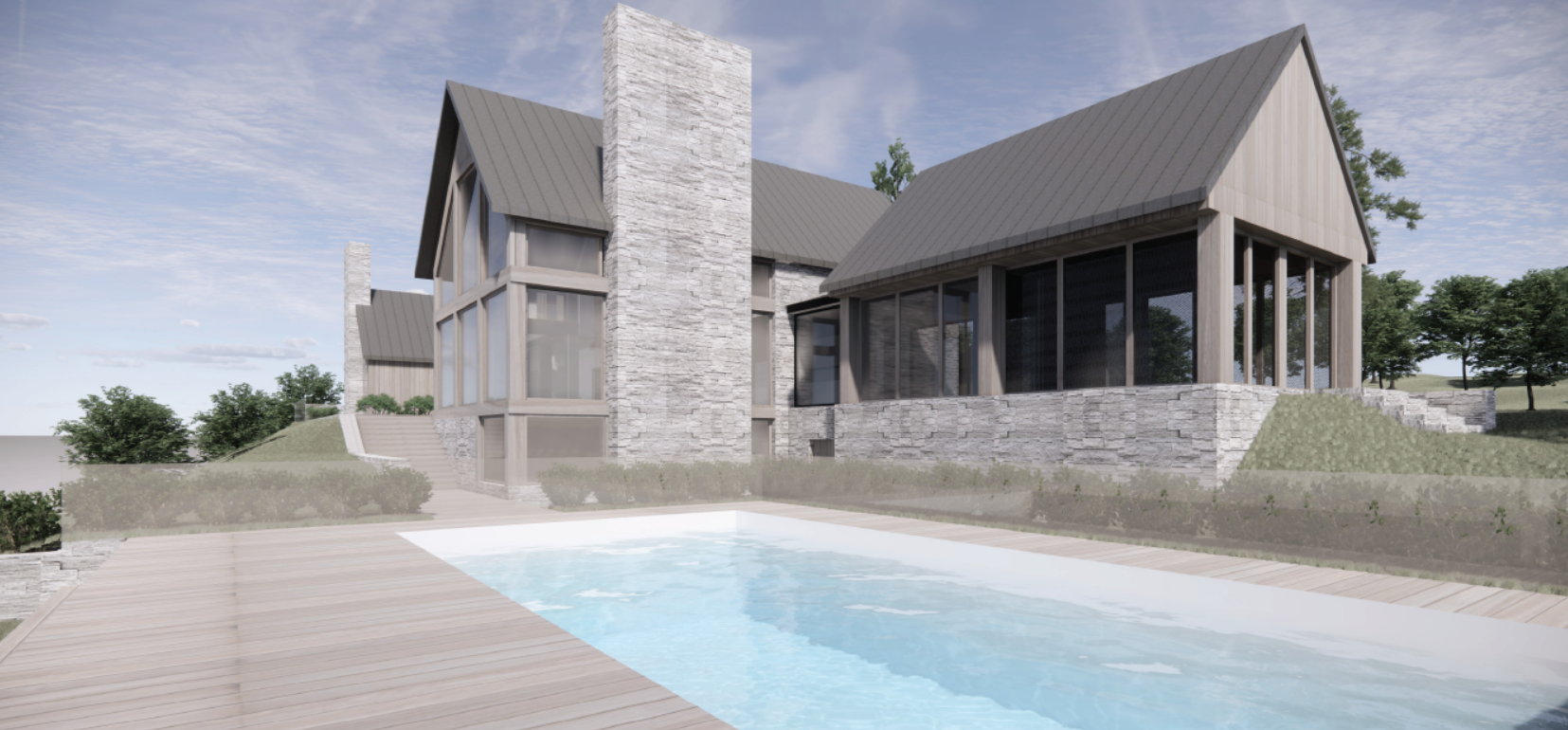

Case Analysis - A project we recently designed in the Northern Shore of Montreal (QC)

Here is a summary of the design of a 12 000 Square Foot Luxury Home in the north shore of Montreal (QC). Windows Wall Ratio is 48%. We added windows overhangs, on south facing portion of the envelope, for passive heating in the winter and to prevent the sun from entering in the summer. Thermal Property of the Envelope was built as per minimum Canada Building Code (Quebec Revision 2010) requirements.

Nominal Cooling Load is around 10 Tons and Nominal Heating Load is around 35 KW. Hot water for space heating and chilled water for space cooling (via radiant loops or forced air) are produced by air to water heat pumps (2 x 5 Tons Each). Produced chilled and hot water are stored in buffer tanks and distributed through radiant loops and forced air Fan Coil Units. The below schematic explains the heat production, storage and distribution:

Hydronic Heating and Cooling Schematics

Load Calculation & Design Results Summary

| Item | Radiant Heating Scenario (100% of Space Heating Load) | Radiant Cooling Scenario (Combined to Radiant Heating) | Forced Air Cooling Scenario (100% of Cooling Load) | Notes / Remarks |

|---|---|---|---|---|

| Nominal Heating Load Density (Btu/hr/ft2) | 12.05 | Nominal Heating Load Divided by the Area of the Property | ||

| Nominal Cooling Load Density (Btu/hr/ft2) | 9.37 | 9.37 | Nominal Cooling Load Divided by the Area of the Property | |

| Supplied Heating Capacity by infloor loops (Btu/hr/ft2) | 12.05 | |||

| Supplied Cooling Capacity by infloor loops (Btu/hr/ft2) | 7 | This is the maximum infloor loops can supply for a floor having a thermal resistance of 1 | ||

| Remaining Ventilation Load Supplied by forced air duct (Btu/hr/ft2) | 2.37 | This is the difference between 9.37 and 7 | ||

| Nominal Air Flow for Cooling (Cubic Feet per Minute) | 2 112 | 4 645 | ||

| % Reduction of Nominal Air Flow due to Radiant Cooling | 55% | |||

| Estimated Ducting Cost $ | 43 140$ | 89 280$ | ||

| Estimated Savings $ | 46 140$ | The difference between 89 280 - 43 140 = 46 140$ |

Conclusion

As shown in the above table, Radiant Floor Cooling is a good money and energy saving option when infloor loops are in the design for space heating. In such a case, it make sense to use the same loop for cooling by running chilled water through the loops and saving on ducting installation cost as well as ventilation energy cost (by simply having less cold air to move through the indoor space). Operating loop supply and return temperatures shall be properly sized so floor surface temperature remains above room ambient air dew point temperature.

In an indoor space, human skin feels radiated heat which also makes comfort level of radiant heating and cooling floors unbeatable when compared to conventional ways of heating and cooling buildings.

We have a large home with natural gas radiant hydronic heating on two floors (6200 sq ft). We enjoy winter warmth but don’t have cooling for summers which are growing hotter.

Wondering if a hydronic cooling system could be added to my existing infloor system. Looking for a a price and installer